Our specialised mining cyclone ceramic tiles provide resistance to abrasion and the protection of material handling cyclone equipment.

Our specialised mining cyclone ceramic tiles provide resistance to abrasion and the protection of material handling cyclone equipment.

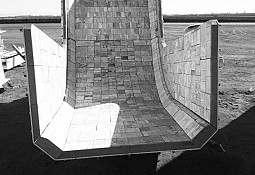

Calyco high efficient and wear-resistant cyclone ceramics contain at least 95% alumina and have good wear, acid, alkali and impact resistance. Different wear resistant ceramic tiles are used as linings in varying positions of the cyclone.

Rectangle ceramic tiles of different thickness are applied to the bottom of a cyclone feed opening depending on wear conditions. Both adhesive and mechanical fixing ensures firm and strong connection and high wear resistance of the ceramic tiles.

Slope-arc ceramic tiles of 5 different shapes and sizes are applied to an overflow and a cone. The combination of these tiles can result in a better cyclone lining result especially for straight seams.

Self-locking grooved ceramic tiles are applied to a cyclone feed cylinder and its bottom. They are also fixed with adhesive for stronger connection.

L-shaped ceramic tiles are applied to the opening end of an cyclone overflow. Both adhesive and mechanical fixing enhances the strength for protecting the side surfaces of the overflow and can prevent the tiles from falling off.

Calyco Mining Cyclone Ceramic Tiles - Coal Preparation Cyclone Ceramic Tile suppliers Australia.

Pressurised two-product DM cyclones are high efficiency equipment for separation of raw coals in coal preparation industry. The are specially designed to minimise the vortex and abrasion and have features such as high top limit, excellent separation efficiency and great handling capacity.

Pressurised two-product DM cyclones are high efficiency equipment for separation of raw coals in coal preparation industry. The are specially designed to minimise the vortex and abrasion and have features such as high top limit, excellent separation efficiency and great handling capacity.

Involute feeding is applied to the cyclones. A great deal of simulation and data analysis shows that involute feed can reduce turbulence generated by abrupt diffusion of the feed at the inlet to allow of smooth and stable flow inside the cyclones for better separation performance.

Involute feeding is applied to the cyclones. A great deal of simulation and data analysis shows that involute feed can reduce turbulence generated by abrupt diffusion of the feed at the inlet to allow of smooth and stable flow inside the cyclones for better separation performance. Our specialised mining cyclone ceramic tiles provide resistance to abrasion and the protection of material handling cyclone equipment.

Our specialised mining cyclone ceramic tiles provide resistance to abrasion and the protection of material handling cyclone equipment.

In a coal preparation plant, Calyco hydraulic classifying cyclones are mainly used for classifying and thickening before flotation and the treatment for coal slurry; and the materials are separated due to their different moving speeds in water. Coal classifying cyclones of different specifications allow wide applications for coals with different quality, sizes and concentrations.

In a coal preparation plant, Calyco hydraulic classifying cyclones are mainly used for classifying and thickening before flotation and the treatment for coal slurry; and the materials are separated due to their different moving speeds in water. Coal classifying cyclones of different specifications allow wide applications for coals with different quality, sizes and concentrations.